|

Research by:

ZeyadZakey |

|

The use of piping systems is ubiquitous in several engineering applications, including process plants, factories, and oil refineries. Concerning the latter, it is of priority to maintain structural integrity of all systems to ensure constant operation. However, due to natural wear and tear, corrosion, or other else, piping systems may become damaged during use. In order to repair the system, it must be isolated. This entails stoppage of operation, resulting in loss of operating time and profit.

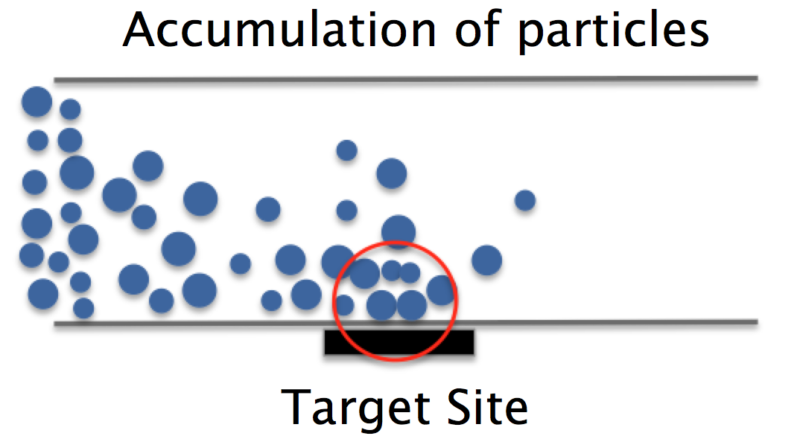

The aim of this project was to propose an alternative method of repair. We hope to investigate a technique where solid particles are inserted into a pipe flow, while an external field is applied to guide the particles to a damage or target site. This is the first step. Secondly, as particles gather at the site, they will be fused in place via some other physical mechanism.

Our study involved the first step of the process, accumulation of particles at the site. The problem setup consists of a fully developed laminar flow within a cylindrical pipe. Solid particles are inserted into the flow. The parameters of interest for the problem are the max flow velocity of the flow, the externally applied magnetic field strength, and the particle radii. The video above shows an example for a velocity of 5 m/s with a 1.5 Tesla magnetic field and a particle size of 200 microns. The video is part of a collaborative work done by Mukherjee et. al. (2013). As part of the paper, a non-dimensional scaling was done. Future work entails running the code with several parameter sets while seeing the relationship to a particle accumulation efficiency.

|

|