|

Research by:

BrettKelly |

|

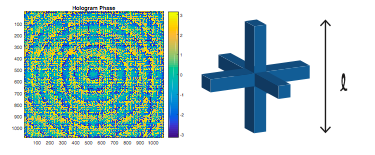

Existing additive manufacturing techniques tend to operate by printing of two-dimensional cross-sections layered on top of one another to form a three dimensional geometry. Optical printing techniques such as photopolymerization by stereolithography have the potential to move towards “true” 3D printing through the use of holographic light shaping. By controlling the phase of an incident coherent wave front there is potential to pattern light in 3 dimensions and cure non-planar geometries in a single exposure. This offers the advantages of increased print speed, the potential to avoid anisotropies induced by layered printing, and the potential to cure 3D volumes in situ. This research is focused on the use of diffractive optical elements, both in the form of electrically-addressed spatial light modulators and nanoimprinted surface relief patterns, to cure photopolymer resins and hydrogels into 3D geometries. To aid in the design of experiments, optical and chemical models have been developed to predict degree of crosslinking spatially throughout a polymerizing 3D volume. Models include those for optical propagation and diffraction as well as chemical species reaction and diffusion. This research aims to apply these printing processes to biological applications such as scaffold fabrication for tissue engineering. |

|