|

|

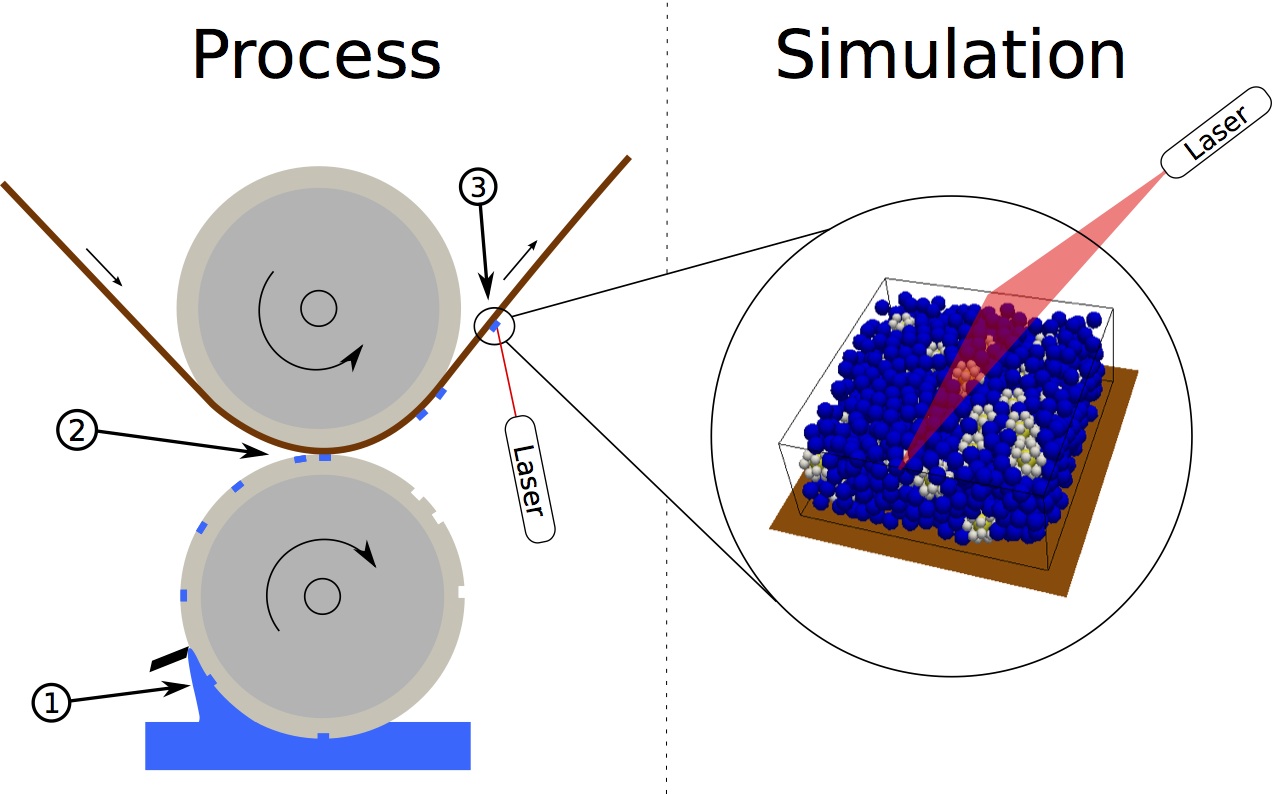

| Roll-to-roll manufacturing has the potential to be a high throughput and low cost technique for producing flexible electronics. Currently, however the inability to control the flow of the inks precisely prevents the creation of the sharp and small features needed to produce electronics. In my research, I am using the Discrete Element Method (DEM) to explore the whether laser ablation can be used to improve the properties of the printed features. A general DEM simulation environment has been written allowing for multiple element types each with distinct properties and interactions relations. To model ablation, particles that reach their evaporation temperature loss mass in accordance with heat input and their heat of vaporization which results in a decrease in radius of the element. If the elements exhibit attract behaviour this can have the result of drawing in surrounding elements. With this simulation framework, we are examining if with different shaped heat sources, intensities and ligand properties it is possible to create different geometries of self assembled nano-particles. Watch the video… |

|