|

Research by:

MarcRussell |

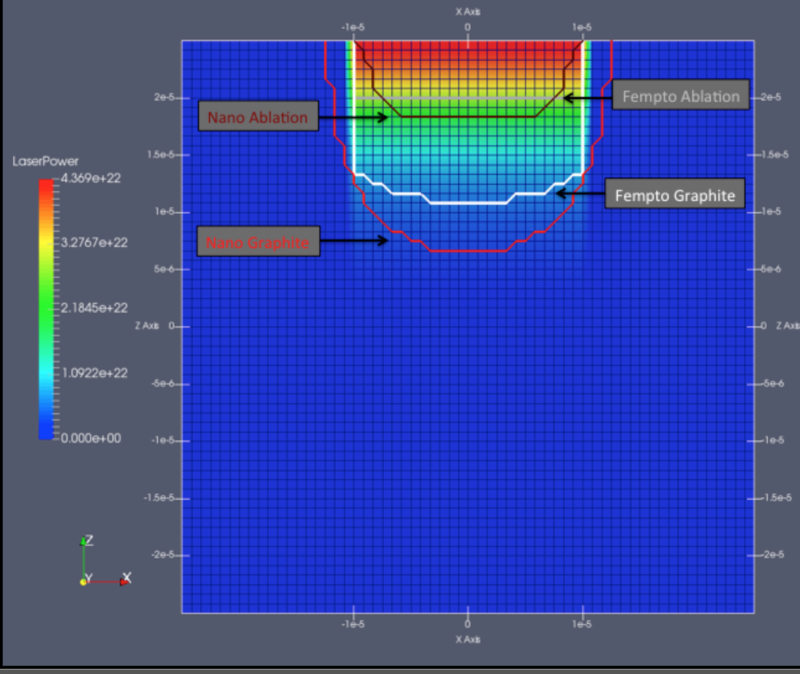

| Micro-machining operations utilize micro-scale machine tools to carry out traditional manufacturing process (e.g. milling, drilling, etc. ) on microscale parts. They can be used for part creation as well as surfacing . Binder-less polycrystalline diamond (BPLCD) has been cited as an ideal machine tool material due to its superior mechanical properties (higher hardness, higher wear resistance, isotropic material properties, etc.) to that of the conventional diamond materials usually used for such tooling. However, because of these properties it is difficult to produce BPLCD tooling using traditional methodologies (grinding, etc.). In addition electrical discharge machining, often used for machining hard materials, cannot be used due to the non-conductance of BPLCD. Laser machining has been proposed as the ideal methodology for machining BPLCD. This work focused on using numerical simulation, in collaboration with experimental results, to predict the laser ablation of a BPLCD diamond material under a variety of lasering conditions to produce the sharpest and deepest ablation profile (ideal for machine tool creation). The use of femtosecond over nanosecond lasering was particularly investigated.Yoshinori Ogawa, Kazuo Nakamoto, Michiharu Ota, Tomohiro Fukaya, Marc Russell, Tarek I. Zohdi, Kazuo Yamazaki, Hideki Aoyama. A study on machining of binder-less polycrystalline diamond by femptosecond pulse laser for fabrication of micro-milling tools. CIRP Annals- Manufacturing Technology. 2016. |

|